10 kW WIND-PV Hybrid SETUP

It includes a Solar PV unit of 6.8 kW and a wind mill of 3.2 kW. It generates approximate 10000 units at a rate of 50 units a day,

In partnership with SunMoksha, a clean technology solutions company from Bengaluru, we have embarked on a unique development of "Renewable Energy Living Laboratory" and build a "Green Campus" that encompasses green solutions for all aspects of the campus operations - renewable energy for electricity generation, for thermal applications in kitchens, water recycling, waste management, waste-to-energy conversion, fully automated and monitored campus and a campus replete with greenery. It has set up renewable energy solutions on the campus and is imparting sustainability training to both students and faculty. For the past several years, it has been conducting competitions for ideas in renewable energy solutions, and in the process, has developed a few prototypes around these ideas. It has created campaigns amongst its students and faculty for awareness and implementation of the best "Green Campus".

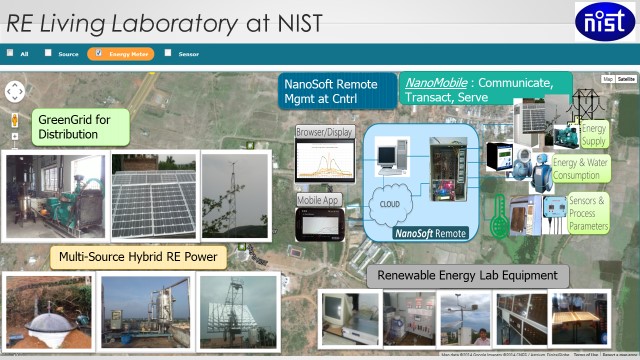

In a first-of-its-kind endeavour in the world, NIST is establishing a unique method of incubating a clean technology solutions company, SunMoksha, to develop, test, and deploy the patented NanoPower solutions for rural homes, farms, and microenterprises. With Odisha Renewable Energy Development Agency (OREDA) playing the lead role, NIST's students, faculty, and staff are collaborating along SunMoksha, to develop, test, and deploy NanoPower solutions to create zero-emission sustainable communities.

In the campus various rated installations of renewable energy resource structures have been installed to test and verify the rural energy feasibility in terms of their availability in the village context. Simplified control and maintenance schemes and the rural manpower skill training have been included to simulate the smart micro grid model for basic rural and micro economic energy interventions.

It includes a Solar PV unit of 6.8 kW and a wind mill of 3.2 kW. It generates approximate 10000 units at a rate of 50 units a day,

It's a Solar Concentrated power unit used for thermal application to generate heat to convert water into steam and facilitate steam based cooking for about 800-1000 meals a day in NIST hostel. It produces heat worth 85000KCal a day which is equivalent to 60kWh-e a day and 9000kWh-e a year/ 5.44kgs of LPG a Day and about 51 LPG cylinders per year.

This is a 1 Ton volumetric plant of kitchen waste-biogas plant producing 70CUM of gas per day. Which is 234kWh-e equivalent per Day and 70325 kWh-e per year and saving about 2 cylinders of LPG worth 27Kgs and about 8064kgs of LPG a year i.e 504 LPG cylinders. The plant consumes less than 5 units of electricity to shred the food waste to slurry and pump them out in to the primary storage.

This unit consists of 20kW gasifier from GEK, All Power Lab, USA which is fed to a biogas run engine-generator set of 15KVA capacity. Which is run at various feeds as wood stocks, rice husk/saw dust briquettes, coconut shells etc. This unit is run for 5hours a day to generate 48kWh-e a day and about 14400 kWh-e a year.

This is a renewable energy based cold storage supplied by New Leaf called as Green Chill. Which does not use any electrical compressor unit but produces an equivalent cooling of about 4 degree Celsius equivalent to a 5TON Compressor runs a 10 TOR cold storage 24x7. The unit saves about 14000kWh-e per year with a recurring cost of only Rs 5000 a year.

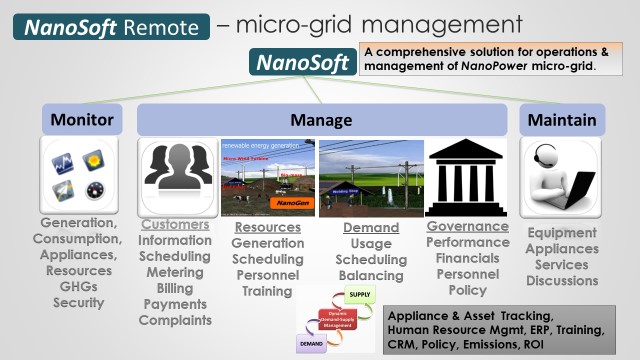

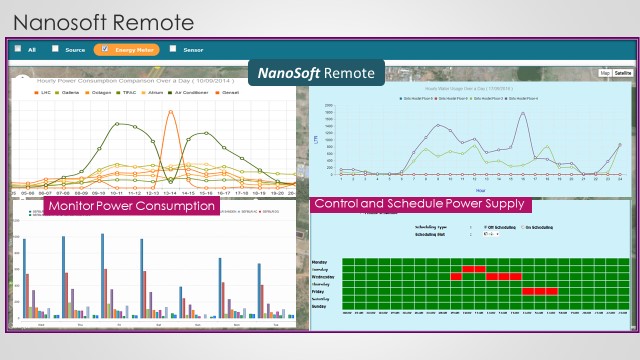

The living Laboratories installed in the campus are used to emulate the field conditions and develop various sensor and networking system including IOT to avail a

precision monitoring and control to the remotely installed system to operate effectively for the purpose with the utmost reliability.

Including the basic syllabus laboratories the students are able to learn the extra that takes to the field. The concept understanding to the customization required in the specific field conditions are better analysed by the use of the green campus technological test bench.

One such experimentation tasking the village conditions to be smoothened to achieve better sustainability in a Cyber Physical Social System the team has led to the development of the "Nano Power" the most advanced and sustainable techno-socio-economic model appreciated all around.

The institute has been facilitating the industry collaborated research and design on Auto Pilot BEV. The students have been constantly been involved in detail from the concepts, designs to the implementations. The BEV design would facilitate to retrofit the present conventional fuel vehicles. The groups of students working on this have qualified for KPIT design contest multiple times and met the Smart India Hackathaon for the retrofit BEV contest.

Putting another feather to this constant encouragement in the Renewable and associated sustainability area of studies, The RE, Embedded & Software research groups have collaborated with professors overseas in various upcoming areas of research and development like predictive control of wind energy conversion system and sustainability of Cyber physical Social System.

Recently the groups have collaborated with University of Buffalo, University of Oklahoma and Xavier University in the above said areas with various prospective goals.

The student group from Renewable energy Clun, NIST had won the Clean Energy based Idea competition in IIT BHU for the idea and prototyping (Proof of Concept) of Filtration of Oil from the Industrial Effuents.

Group of Members from Renewable Energy Group had won the prestigious Sustainability Contest and workshop by Wipro Limited, Bengaluru at PAN India Level. The students had worked on the assigned problem areas of sustainability analysis and suggesting mitigation on the given guidelines. NIST was the only Private Engineering College among all other Top 10 who are the IITs, IIMs and Top Universities of India.

The deployment of the NIST Embedded software group test bench genesis "Nano Power" and "Smart Nano Grid" in Chhotkei village in remote Satakoshia Tiger Reserve, Odisha was a path breaking village microgrid solution and it was not until it was agreed by the Smart city India group and awarded us with the Smart village award. The groups still are working on the field fed issues to develop smarter versions of the same.

All these focused research and development followed by immediate implementation as Proof of Concept and field deployment has been realized by the state energy authorities to bestow us with the best performance categories in the Odisha State Energy Conservation Award on the World Energy Conservation Day in sequel for last three years.

Last but not the least the Department of Forest and Environment, Govt. of Odisha awarded NIST for its outstanding performance plantation and afforestation work in 2016.